Processing Capacity: 0.65-130t/h

Feeding size: ≤25mm

Applied material: Quartz sand, fluorite ore, coal slime, feldspar, copper ore, clinker, slag, bauxite, ceramsite sand, etc.

Application field: Cement, new building materials, refractories, fertilizer and metal processing, glass and ceramics production industries

Dry ball mill is mainly composed of barrel, end cover, main bearing, hollow journal, transmission gear and feeder. The cylinder is welded with 15-36mm thick steel plate, and its wear resistance is very high. In particular, the gear is hobbed by steel casting, and the cylinder body is inlaid with wear-resistant manganese steel lining plate, which has good wear resistance, and the whole machine runs stably and reliably.

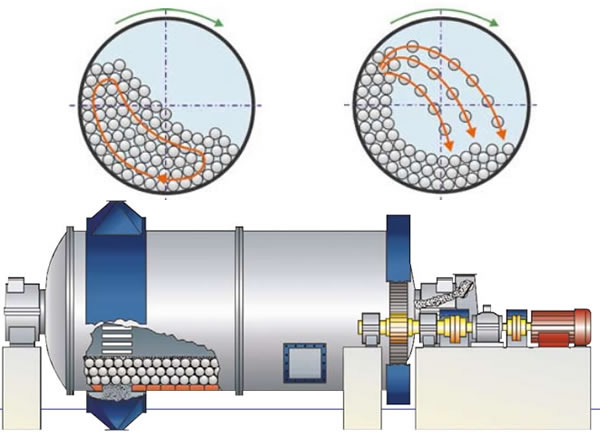

The dry ball mill is a horizontal cylindrical rotating device, which is driven by gears, chain wheels or belts. It is a two bin grid type ball mill. The material of this type of dry ball mill is evenly and evenly entered into the first bin of the equipment by the feeding machine through the feeding hollow shaft, which contains three kinds of ball media of different specifications. The rotation of the cylinder generates centrifugal force to bring the ball medium to a certain height and then fall down, which has a heavy impact and grinding effect on the materials. After coarse grinding in the first bin, the material enters into the second bin through the single-layer partition plate, which contains four different specifications of ball media to further grind the materials. The powder is discharged through the screen fence at the discharge port and enters the vibrating screen powder machine for grading to complete the grinding operation.

1. The inner lining of the cylinder is made of wear-resistant materials, so as to enhance the wear resistance and prolong the service life; and the drum feeder and combined feeder can be provided to meet the requirements of different users.

2. The groove type annular lining plate increases the contact surface of ball and ore, enhances the grinding effect, and has the lifting ability to the ore and reduces the energy consumption.

3. The cone design is adopted at the discharge end, which not only increases the volume, but also forces the material and steel ball grading at the cone end. The closer to the outlet, the smaller the diameter of the steel ball, which increases the repeated grinding effect.

4. The dry ball mill will replace the bearing bush sliding bearing with rolling bearing, saving energy by 10% - 20%; in addition, the machine is equipped with integral large plate, which can shorten the installation time and reduce the installation requirements.

1. The operation and maintenance personnel of dry ball mill should be familiar with the structure and performance of crushing equipment and the name, specification and function of each part.

2. The operator shall follow the "four fixed" principle and lubricate according to the requirements of each part marked in the lubrication diagram. Untreated waste oil shall not be used and the lubricating points shall be kept clean.

3. During operation, pay attention to check that the bearing temperature of each part does not exceed 60 ℃, and check whether the bolts of each part are loose, whether there is abnormal sound, whether the feed water is uniform, and whether the motor current and voltage are normal.

4. Keep the environment of the equipment clean and clean. Except for the operation part, all other parts should be handled at any time.

| Model | Rotary speed(r/min) | Balls load(t) | Feeding size(mm) | Discharge size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| 900*1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900*3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200*2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200*3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200*4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500*3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500*4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500*5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830*3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830*4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830*6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 180 | 34 |

| 1830*7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 210 | 38 |

| 2100*3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| 2100*4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100*7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200*4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| 2200*6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| 2200*7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| 2200*7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| 2400*4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| 2700*4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| 2700*4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 |

| 3200*4500 | 18 | 65 | ≤25 | 0.074-0.4 | 25-130 | 800 | 147 |

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660