Processing Capacity: 0.65-130t/h

Feeding size: ≤25mm

Applied material: Steel slag, lime, gold ore, aluminum powder, quartz sand, aluminum paste, hematite, high alumina porcelain, iron concentrate, fluorite, barite, slime, potassium feldspar, tungsten carbide, copper ore,

Application field: cement, new building materials, refractories, fertilizer and metal processing, glass and ceramics production industries

Energy saving ball mill is our company in order to meet the production needs of the majority of customers to build a professional ball mill, the ball mill in production, the working principle is basically the same as other ball mills, only in the size of a lot of reduction, in the production conditions are relatively poor, the production efficiency of small ball mill is much higher than other ball mills of the same type.

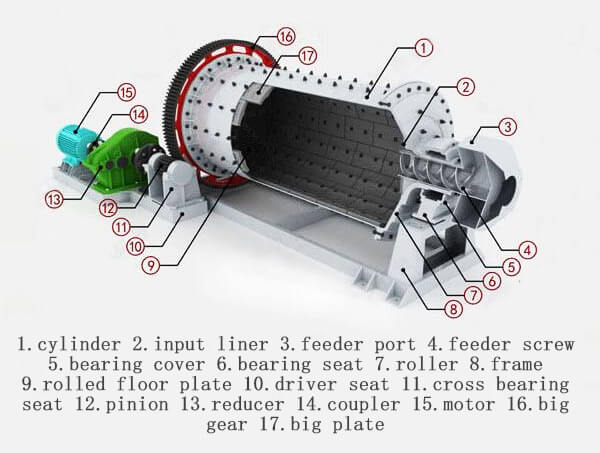

The energy saving ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control), etc. The hollow shaft of ball mill is made of cast steel, the inner lining can be disassembled and replaced, the rotary gear is processed by casting gear hobbing, and the barrel of ball mill is inlaid with wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and reliably.

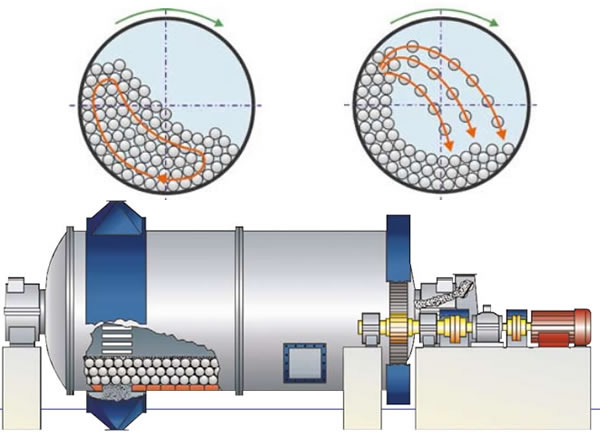

The material enters the first silo of the mill spirally through the feeding device through the hollow shaft of the feeding material. There is a stepped lining or a corrugated lining in the hopper, which contains steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder brings the steel balls to a certain height After falling, it has a heavy impact and grinding effect on the material. After the material is coarsely ground in the first bin, it enters the second bin through a single-layer compartment board. This bin is inlaid with a flat liner and steel balls inside to further grind the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

The energy-saving ball mill has changed the original structure of the mill, so that the machine body and underframe are integrated. When installed, it can be suspended on the foundation plane at one time. The main shaft is supported by double row centripetal spherical roller bearing, which can reduce energy consumption by 30%. It can improve the fineness of the mill and increase the processing capacity by 15-20%. The energy-saving ball mill uses the rotating bearing instead of the sliding bearing.

Advantages of energy-saving ball mill: compared with the traditional ball mill, the motor power matched by the cone mill can be reduced by 18 - 25%, lubricating oil 70%, cooling water 90% and comprehensive energy saving more than 20%. Under normal circumstances, there is no need to replace the main bearing for 8 years, saving a lot of maintenance costs; the main bearing lubrication uses grease, which is convenient and clean, and avoids heavy metal pollution; the use of this product does not change the production process and technical parameters, does not change the assembly size and installation size of the mill, which is suitable for the energy-saving technical transformation of the existing mill, and is also suitable for manufacturing a new mill.

Installation of energy-saving ball mill: the energy-saving ball mill should be installed on a solid concrete foundation. For the foundation design and construction of energy-saving ball mill, please refer to the general assembly drawing and foundation drawing of energy-saving ball mill. In order to ensure that the position accuracy of each part of the energy-saving ball mill does not change greatly, the foundation of the energy-saving ball mill should adopt the whole block structure.

| Model | Rotary speed(r/min) | Balls load(t) | Feeding size(mm) | Discharge size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| 900*1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900*3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200*2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200*3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200*4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500*3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500*4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500*5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830*3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830*4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830*6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 180 | 34 |

| 1830*7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 210 | 38 |

| 2100*3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| 2100*4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100*7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200*4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| 2200*6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| 2200*7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| 2200*7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| 2400*4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| 2700*4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| 2700*4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 |

| 3200*4500 | 18 | 65 | ≤25 | 0.074-0.4 | 25-130 | 800 | 147 |

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660