Processing Capacity: 0.65-130t/h

Feeding size: ≤25mm

Applied material: Steel slag, lime, gold ore, aluminum powder, quartz sand, aluminum paste, hematite, high alumina porcelain, iron concentrate, fluorite, barite, slime, potassium feldspar, tungsten carbide, copper ore,

Application field: cement, new building materials, refractories, fertilizer and metal processing, glass and ceramics production industries

Introduction

Ball mill is suitable for grinding all kinds of ore and other materials,it is widely used in beneficiation, building materials and chemical industries. The ball mill is composed of the feeding part, the discharging part, the turning part, the transmission part (reducer, small transmission gear, motor, electronic control) and other main parts. The hollow shaft is made of cast steel, and the inner lining can be replaced. The rotary gear is processed by casting hobbing. The cylinder is equipped with a wear-resistant lining, which has good wear resistance, stable operation and reliable performance.

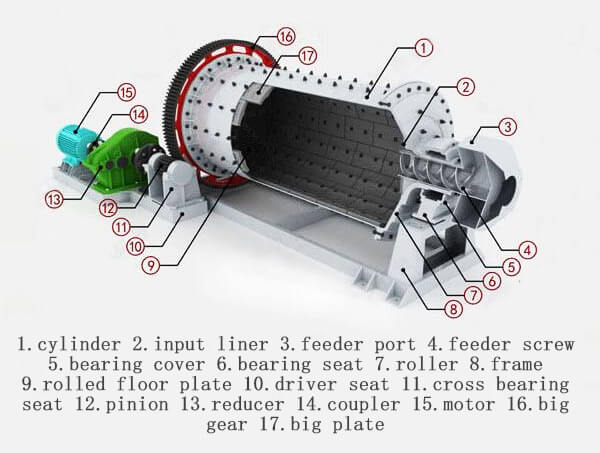

Structure of ball mill

The ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control), etc. The hollow shaft of ball mill is made of cast steel, the inner lining can be disassembled and replaced, the rotary gear is processed by casting gear hobbing, and the barrel of ball mill is inlaid with wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and reliably.

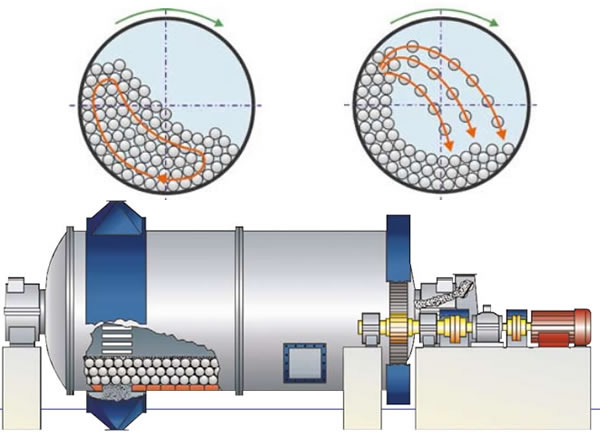

Working principle

The material enters the first silo of the mill spirally through the feeding device through the hollow shaft of the feeding material. There is a stepped lining or a corrugated lining in the hopper, which contains steel balls of different specifications. The centrifugal force generated by the rotation of the cylinder brings the steel balls to a certain height After falling, it has a heavy impact and grinding effect on the material. After the material is coarsely ground in the first bin, it enters the second bin through a single-layer compartment board. This bin is inlaid with a flat liner and steel balls inside to further grind the material. The powder is discharged through the discharge grate plate to complete the grinding operation.

Performance advantages

1. High wear resistance and impact resistance (lining plate)

Through the advanced double medium quenching process, the lining plate can bear the huge impact force in the production, and can keep the surface shape of the lining plate for a long time in the production, so as to reduce the deformation and wear of the lining plate.

2. The liner has strong adaptability

Compared with the high manganese steel lining plate on the market, the ball mill lining plate produced by shuguang machinery adopts medium alloy double medium quenching medium alloy steel, which shows high cost performance and can adapt to wet grinding, dry grinding and mixed grinding of various mine rocks.

3. High bending strength of gears

The use of modified gears in ball mill accessories can eliminate undercutting phenomenon, strengthen the gear with weak bending strength, and increase the bending strength of gear teeth by more than one time.

4. Good lubrication and reliable operation

The modified gear can reduce the sliding speed and sliding ratio of meshing, so as to improve the wear resistance and scuffing resistance of the gear, improve the hydrodynamic performance and lubrication state of the gear transmission, and improve the operation reliability of the ball mill.

5. Heat insulation and cooling, long life (bearing)

The diameter of the hollow shaft in the rolling bearing of the ball mill is thickened, which makes the radial distance between the rolling bearing and the feeding and discharging spiral tube enlarged, which plays a certain role in heat insulation and cooling and prolongs the service life of the bearing.

6. Energy saving, less wear and tear

The use of thin oil lubrication instead of grease lubrication can prevent poor lubrication due to lack of oil, reduce the friction coefficient of bearings and other components, and greatly reduce the loss rate of components.

| Model | Rotary speed(r/min) | Balls load(t) | Feeding size(mm) | Discharge size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| 900*1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900*3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200*2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200*3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200*4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500*3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500*4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500*5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830*3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830*4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830*6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 180 | 34 |

| 1830*7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 210 | 38 |

| 2100*3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| 2100*4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100*7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200*4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

| 2200*6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 370 | 52.8 |

| 2200*7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| 2200*7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| 2400*4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 65 |

| 2700*4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 400 | 94 |

| 2700*4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 430 | 102 |

| 3200*4500 | 18 | 65 | ≤25 | 0.074-0.4 | 25-130 | 800 | 147 |

Quality: the core parts are made of high-performance wear-resistant alloy material, with high wear resistance and low cost. The motor adopts national standard products to ensure the quality of the equipment.

Price: strict production process, automatic production equipment and direct selling by manufacturers make the cost of shuguang machine relatively low on the basis of ensuring product quality. In addition, it adopts the marketing mode of small profit and high sales, which belongs to the positioning of intermediate products in the market, with high cost performance. This is also the reason why many customers choose red star.

After sales: for mechanical equipment, after-sales is very important. When users install the equipment, shuguang machine will send professional engineers to guide the installation on site, and train the operation until the user can operate independently, and train the equipment performance, basic operation methods and troubleshooting, so that users can use more easily. In case of equipment failure in later stage, the manufacturer will be on standby at any time , reply quickly in a short time and arrange special person to solve the problem.

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660