Processing Capacity: 5-50t/h

Feeding size: ≤40

Applied material: River pebble, calcite, quartz, glass, marble, pebble, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, diabase, granite, basalt, etc.

Application field: coal, metallurgy, mining, chemical industry, building materials and other industries.

Double Roller crusher, a kind of mining machinery, is also called double roll crusher. It is mainly used for crushing ore. This machine has the advantages of small volume, large crushing ratio (5-8), low noise, simple structure and convenient maintenance. The crushed material has uniform particle size, low over crushing rate, convenient maintenance, sensitive overload protection, safety and reliability. It is suitable for coal, metallurgy, mining, chemical industry, building materials and other industries. It is more suitable for crushing raw coal (including gangue) in large coal mines or coal preparation plants.

1.It has the advantages of compact structure, light weight, small volume, simple structure, small occupied space and convenient operation and maintenance,stable operation, high efficiency and energy saving, high crushing efficiency and adjustable discharge particle size.

2.Double roll crusher is equipped with dust-proof plate, which has good sealing performance, avoids the splashing of small materials after crushing, with less dust, low working noise and greatly improved working environment.

3. The grinding roller body is optimized again, and it is not necessary to change the grinding roller body for the whole life of the equipment. However, the old type roller pair machine needs to be disassembled and overhauled after one year's use.

4.A replaceable wear-resistant lining plate is installed on the grinding roller of the double roll crusher. The wear-resistant lining plate is made of domestic advanced wear-resistant materials, which has the advantages of long service life, not easy to be damaged and convenient for maintenance. The continuous service life can reach more than one year. When the wear is serious, the cover can be replaced by moving the cover. The maintenance quantity is small, the cost is low, this is any domestic other type crusher is incomparable.

5.The roller crusher is equipped with safety protection device. When there is an accident of metal iron pieces entering the crushing chamber, the protective device will act and the iron parts will leak out and the equipment will operate normally.

6.The gap of abrasive roller body of the opposite roller crusher can be adjusted from 1 mm to 20 mm. After adjusting the gap according to the requirements of crushing particle size, the crushing particle size can be controlled reliably and discharged from the bottom of crushing chamber with ideal particle size.

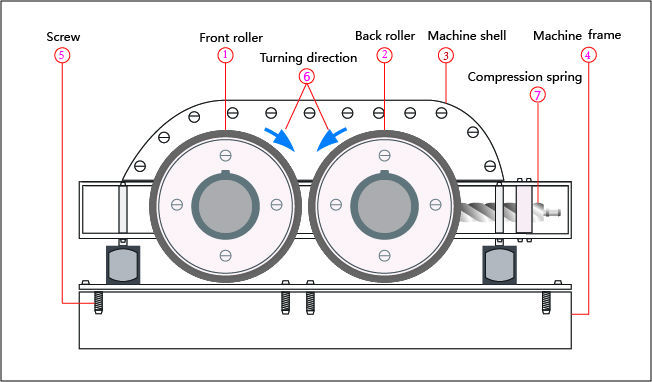

The roller crusher is mainly composed of frame, body, roller, roller supporting bearing, pressing device, adjusting device and driving device (transmission part and power part).

Frame: welded by section steel, mainly for support, all parts are installed on the frame.

Body: made of high-quality cast iron, it is a split structure of upper and lower parts, and is cast into a closed box. The roller is installed in the box. In order to prevent the body from wearing, wear-resistant lining plates are installed on both sides of the cover.

Roller: the main part of crushing roll, inlaid on the main and auxiliary shafts.

Driving device: there are motor driving and passive pulley rotation, and the power is transmitted to the roller support bearing through the triangle belt. The chain wheel and the chain wheel are driven by the main roller and the reverse direction.

In the process of using roller crusher, the wear of vulnerable parts is a problem of concern to customers. The main working part of roller crusher is the crushing roll, which bears high pressure. Due to the uncertainty of crushing materials, the crushing roller is prone to wear and corrosion in varying degrees after working for a period of time. In view of the above problems, the solution of Hongxing roller crusher manufacturers is to build hard alloy on the surface of vulnerable parts, so as to achieve the effect of wear resistance, heat resistance and corrosion resistance, which can significantly improve the service life of crushing roller and save maintenance costs.

Two groups of separately driven rollers are used for roll breaking. After the crusher is started, the two roller wheels rotate in opposite direction to form a "V" shaped crushing chamber. The material is fed into the crusher from the hopper in a certain amount, and the tangential direction enters the middle of the two rollers. Because the gap between the rollers is small and the system strength is far greater than that of the materials (the roller spacing will not be increased or the roll path motion state will not be changed due to the high hardness of the material) The material in the middle of the two rollers will be crushed into a small particle size with the rotation of the opposite roller, and then enter the bottom of the machine with the rotation direction of the roller, and flow out of the machine from the inclined material trough to complete the whole crushing process.

The distance between the two rollers of crusher is the width of discharge port, which determines the acceptable size of crushed materials.

| Model | Feed size(mm) | Discharge size(mm) | Yield(t/h) | Motor power(kw) | Weight(t) |

| 2PG-400*250 | ≤25 | 1-8 | 5-10 | 11 | 1500 |

| 2PG-610*400 | ≤40 | 1-20 | 13-35 | 30 | 4500 |

| 2PG-750*500 | ≤40 | 2-20 | 15-40 | 37 | 12250 |

| 2PG-900*500 | ≤40 | 3-40 | 20-50 | 44 | 14000 |

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660