Processing Capacity: 1.5-20t/h

Feeding size:

Applied material: magnetic, heavy and float concentrates of metal and non-metallic minerals, clay of cement industry and coal slime of coal industry

Application field: Chemical, metallurgy, building materials, mining and other industries

Drum dryer is also known as drum drying equipment or rotary drum dryer, which is the most common and widely used drying equipment in mining equipment. It is suitable for drying magnetic, heavy and float concentrates of metal and non-metallic minerals, clay of cement industry and coal slime of coal industry.It has the advantages of reasonable structure, excellent production, high output, low energy consumption and convenient operation.

1. The dryer designed and produced with multi-combination lifting device has made many technological innovations in the lifting device system. It adopts a new multi-combination lifting device and overcomes the "wind tunnel" of traditional dryers. Phenomenon, the thermal efficiency is high, and the coal consumption is reduced by about 20%.

2. It is suitable for a variety of combustion furnaces: high temperature boiling furnace, coal powder injection furnace and manual coal charging furnace.

3. The transmission gears adopt pin-changeable gears, which replace the traditional cast steel gears, saving cost and investment, and greatly reducing maintenance costs and time.

4. The use of a centralized control system can realize the computer-based central monitoring and management of large enterprises.

5. Larger production capacity and continuous operation;

6. Simple structure and convenient operation;

7. Fewer failures and low maintenance costs;

8. It has a wide range of applications, it can be used to dry granular materials, and it is also very beneficial for those materials with high adhesion;

9. The operation flexibility is large, and the output of the product is allowed to have a large fluctuation range in production, which will not affect the quality of the product;

10. Easy to clean.

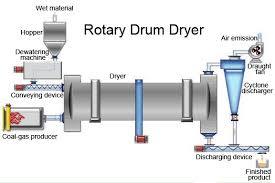

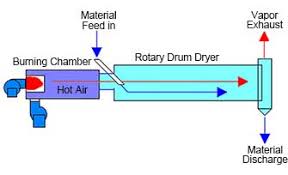

Wet materials are sent to the hopper by belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipe through the feeder of hopper.The inclination of the feeding pipe should be greater than the natural inclination of the material so that the material can flow smoothly into the dryer.The material is added from the higher end, and the heat carrier enters from the lower end, and it comes into countercurrent contact with the material, and there is also the heat carrier and the material flow into the cylinder side by side.When the wet material moves forward in the cylinder, it directly or indirectly receives heat from the heating medium, so that the wet material can be dried, and then sent out through a belt or screw conveyor at the discharge end.A copy board is installed on the inner wall of the cylinder. Its function is to pick up and scatter the materials to increase the contact surface between the materials and the airflow to increase the drying rate and promote the advancement of the materials. The heating medium is generally divided into hot air, flue gas, etc. After the heating medium passes through the dryer, a cyclone dust collector is generally required to capture the materials carried in the gas. If it is necessary to further reduce the dust content of the exhaust gas, it should be discharged after passing through a bag filter or a wet dust collector.

| Model | Rotation speed(r/min) | Slope(o) | Inlet temperature(℃) | Power(kw) | Capacity(t/h) | Weight(t) |

| 0.6*10 | 3.8-5 | 3-5 | 700 | 4-6 | 1.5-9 | 3.2 |

| 0.8*10 | 3.8-5 | 3-5 | 700 | 4-6 | 1.8-10 | 3.8 |

| 1.0*10 | 3.8-5 | 3-5 | 700 | 5.5-7.5 | 2.2-10 | 7.5 |

| 1.2*12 | 3-4 | 3-5 | 700 | 11-13 | 2.7-15 | 13.1 |

| 1.5*10 | 2.8-4 | 3-5 | 700 | 13-15 | 2.7-17 | 17.9 |

| 1.5*12 | 2.8-4 | 3-5 | 700 | 15-17 | 2.7-17 | 22.3 |

| 1.5*15 | 3 | 3-5 | 700 | 15-18.5 | 3.0*20 | 25.6 |

| 1.8*14 | 2-4 | 3-5 | 700 | 18.5 | 3-12 | 29 |

| 2.2*12 | 2-4 | 3-5 | 700 | 22 | 5-16 | 53 |

| 2.2*18 | 2-4 | 3-5 | 700 | 30 | 8-20 | 53 |

1. The installed dryer should be tested in an empty machine for no less than 4 hours, and any abnormal situation during the test run should be dealt with in time.

2. After the test run, tighten all the connecting bolts again, check and replenish the lubricating oil, and start the load test run after the test run is normal.

3. Before the load test, the auxiliary equipment should be tested in an empty run. After a successful single-machine test run, it will be transferred to a joint test run.

4. Ignite the hot air oven to preheat the dryer and turn on the dryer at the same time. It is forbidden to heat the cylinder without turning to prevent the cylinder from bending.

5. According to the preheating situation, gradually add wet materials into the drying cylinder, and gradually increase the feeding amount according to the moisture content of the discharged materials. The dryer needs to have a process to preheat, and the hot blast stove should also have a process to prevent sudden fire. Prevent local overheating, uneven thermal expansion and damage.

6. The level of fuel burn value, the quality of insulation of each part, the amount of moisture in the wet material, and the uniformity of the feeding amount affect the quality of the dried product and the fuel consumption. Therefore, to achieve the best possible state of each part is an effective way to improve economic efficiency.

7. In the working state, the supporting roller frame should be filled with cooling water. All lubrication parts should be refueled in time.

When parking, the hot blast stove should be turned off first, and the drying cylinder should continue to rotate until it cools to the outside temperature before stopping. It is forbidden to stop at high temperature to prevent bending and deformation of the cylinder.

8. In the event of a sudden power failure, the hot blast stove should be turned off immediately, the feeding should be stopped, and the cylinder body should be rotated for half a turn every 15 minutes until the cylinder body is cooled. Special personnel should be responsible for this operation procedure. Violation of this procedure will cause the cylinder to bend. Severe bending of the barrel will make the dryer unable to operate normally.

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660