Processing Capacity: 50-3000t/h

Feeding size: ≤1500mm

Applied material: Kaolin, dolomite, limestone, feldspar, limestone, slag, slag stone, marble, pebble, river pebble and other hundreds of materials

Application field: Mining, cement, chemical industry, road construction, refractory materials, construction site, sand and gravel plant and other industries

Heavy hammer crusher has the advantages of low operating cost, small supporting power, low production cost, large feed size, large crushing ratio, small product size, etc., which is widely used in mining industry.

This product is crushed by the impact of high-speed hammer body and material. It has the characteristics of simple structure, large crushing ratio, high production efficiency, and no need of primary crushing. It can be broken in two forms of dry and wet. It is suitable for crushing medium and medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, combustion and other departments. The equipment can adjust the gap between hammer head and liner according to the user's requirements, and change the discharge particle size to meet the different needs of different users. The hammer head of the equipment is made of train wheel hub steel by forging. The shape of lining plate is similar to that of jaw plate. It is made of 13 manganese steel with small investment and quick effect.

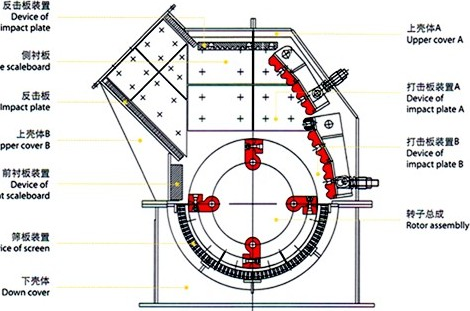

The heavy hammer crusher is composed of casing, rotor, striking plate, hammer head, support and lining plate.

The specific working principle is: the motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port and crushed by the impact, impact, shearing and grinding of a high-speed hammer. In the lower part of the rotor, there is a sieve plate. In the crushed materials, the particles smaller than the mesh size are discharged through the sieve plate, and the coarse particles larger than the mesh size are retained on the sieve plate and continue to be hit and ground by the hammer, and finally discharged through the sieve plate.

1. During the operation, it is necessary to monitor whether all kinds of instruments are normal and whether the components have abnormal sound.

2. The electrical interlock system of crusher oil pressure cannot be removed under any circumstances.

3. When the machine is running, people shall not stick to the rotating surface of jaw crusher.

4. During operation, personnel are not allowed to take large ore or other articles into the machine by hand.

5. When dealing with the blocking of jaw crusher, the ore at the head of the feeder should be first treated, and then the ore should be treated from the upper part. It is forbidden to treat with turning gear or from the lower part of the discharge port upward.

6. When dealing with the blockage of the lower funnel of jaw crusher, it is necessary to contact the positions of ore feeder and belt conveyor, disconnect the power switch of belt conveyor, and assign special personnel to monitor.

1. It has the advantages of large feed size, high fineness ratio and high efficiency;

2. Simple structure, compact assembly and light weight;

3. The particle size of the product is uniform, and there is little broken powder;

4. Easy maintenance and little wear;

5. The advantages of low power consumption, is used as medium and fine crushing equipment.

| Model | Rotor diameter*length(mm) | Feed port size(mm) |

Feed particlesize(mm) | Production capacity(t/h) | Power(kw) | Appearance size(mm) |

| 0706 | 700*570 | 618*510 | ≤400 | 50-70 | 75 | 1950*1340*1480 |

| 0808 | 800*750 | 750*610 | ≤500 | 80-100 | 132 | 2280*1790*1670 |

| 0910 | 900*1000 | 1070*750 | ≤600 | 150-200 | 110*2 | 2600*2200*1940 |

| 1012 | 1000*1180 | 1255*810 | ≤650 | 250-300 | 132*2 | 2800*2310*2210 |

| 1213 | 1200*1280 | 1350*920 | ≤750 | 300-350 | 160*2 | 2970*2580*2510 |

| 1216 | 1200*1590 | 1530*920 | ≤750 | 400-500 | 200*2 | 3070*2840*2580 |

| 1220 | 1200*1950 | 2000*920 | ≤750 | 500-600 | 220*2 | 3080*3380*2580 |

| 1310 | 1310*1050 | 890*1075 | ≤650 | 150-180 | 160 | 2950*2250*2495 |

| 1510 | 1500*950 | 1000*900 | ≤700 | 160-210 | 132*2 | 3260*2414*2750 |

| 1512 | 1500*1160 | 1200*900 | ≤750 | 250-320 | 160*2 | 3260*2624*2750 |

| 1615 | 1650*1452 | 1500*1200 | ≤1000 | 420-500 | 200*2 | 3667*2937*3436 |

| 1620 | 1660*1900 | 2000*1200 | ≤1200 | 800-1000 | 400*2 | 3667*3200*3436 |

| 1820 | 1800*1964 | 2000*1200 | ≤1200 | 1000-1200 | 450*2 | 3700*3270*3515 |

| 2125 | 2100*2485 | 2530*1560 | ≤1500 | 1800-3000 | 1250 | 4455*4565*4670 |

Our sales team is available to respond to any queries you might have on ShuGuang. Get in touch using the details below:

Address No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China

0086-371-67666660